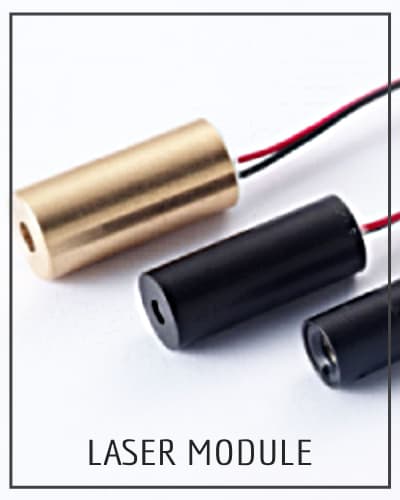

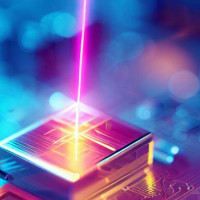

雷射模組產品編碼表

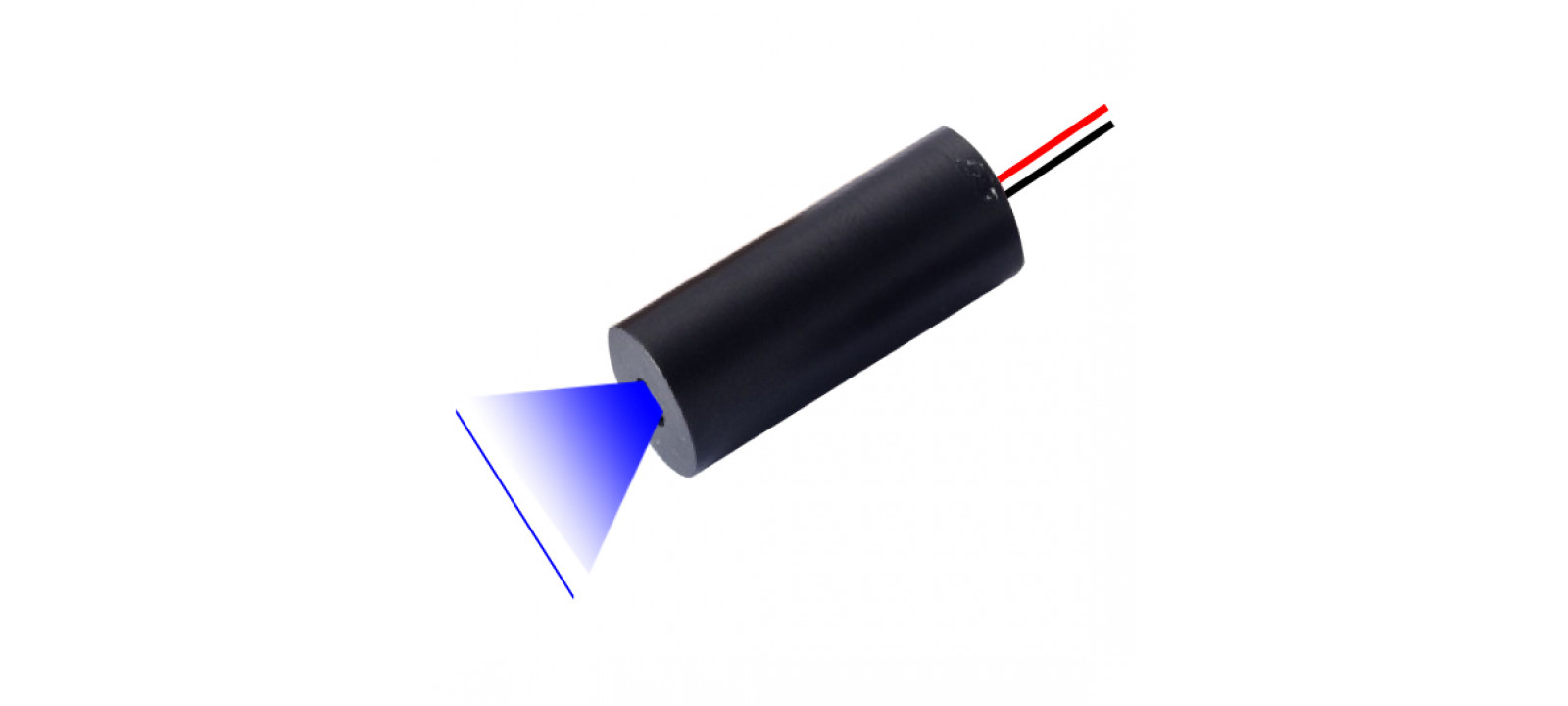

RGB 可見光雷射模組、紅外線雷射模組、線型雷射模組、一字線雷射、十字線雷射

| 產品代號 | 雷射模組直徑(mm) | 顏色, λ(nm) | 樣式 | 雷射功率(mW) | 雷射圖形 |

| LM: | 4: 4mm | B: 藍光, 405nm | S: 標準 | <0.39mW, Class I | D: 點狀, R: 圓點 |

| Laser Module | 6: 6mm | G: 綠光, 520nm | H: 高規 | 1: <1mW, Class II | L: 一字線, C: 十字線 |

| Laser Module | 8: 8mm | R: 紅光, 635nm | M: 超穎透鏡 | 10: <10mW | P: 特殊圖案 |

| IR Module | 9: 9mm | IR: 紅外光, 940nm | 1000: <1000mW |

憑藉在雷射模組與雷射感測器的專業經驗,我們提供 RGB 可見光雷射模組、IR 紅外線雷射模組、線型雷射模組、一字線雷射模組、十字線雷射模組、均勻線雷射模組,以及各類客製化雷射模組。

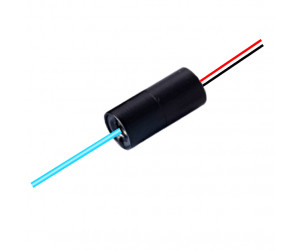

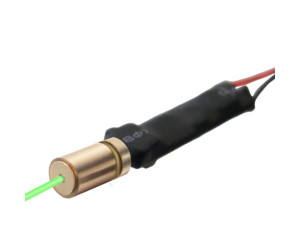

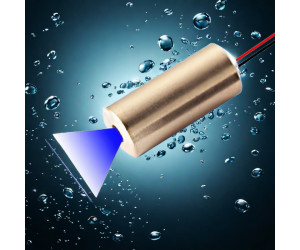

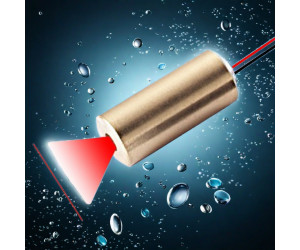

- RGB 雷射模組 / 二極體雷射模組: 405nm, 450nm, 490nm, 520nm, 635nm, 650nm 可見光雷射模組,適用於投影、照明與對準系統。

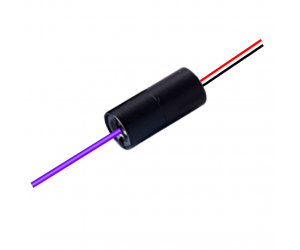

- IR 雷射模組 / 紅外線雷射模組: 波長涵蓋 780nm, 830nm, 850nm, 940nm, 980nm,可用於感測、紅外線投影及精密定位應用。

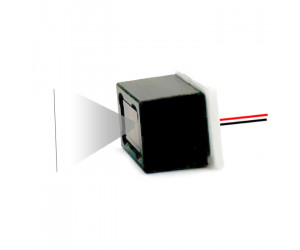

- 一字線雷射模組 / 十字線雷射模組: 提供 RGB 與紅外線線型雷射、一字線雷射、十字線雷射與均勻線雷射模組。

- 其他雷射模組與 DOE 雷射模組: 高功率雷射模組、VCSEL 雷射二極體模組、結構光雷射模組與超穎透鏡客製化雷射模組。 詳情請參考 客製化雷射光源。

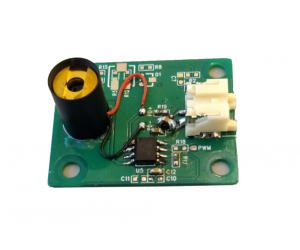

- TTL 雷射調變: 支援系統開發者透過 PWM duty ratio 10%~100% 調整輸出功率,方便快速找出最佳功率。

- 防水雷射模組: 設計符合 IP67 標準防水雷射模組,詳情請參考 產品頁面。

- 雷射安全: 遵循 IEC 60825-1 標準,降低操作與眼睛安全風險,詳情請參考 雷射安全指南。

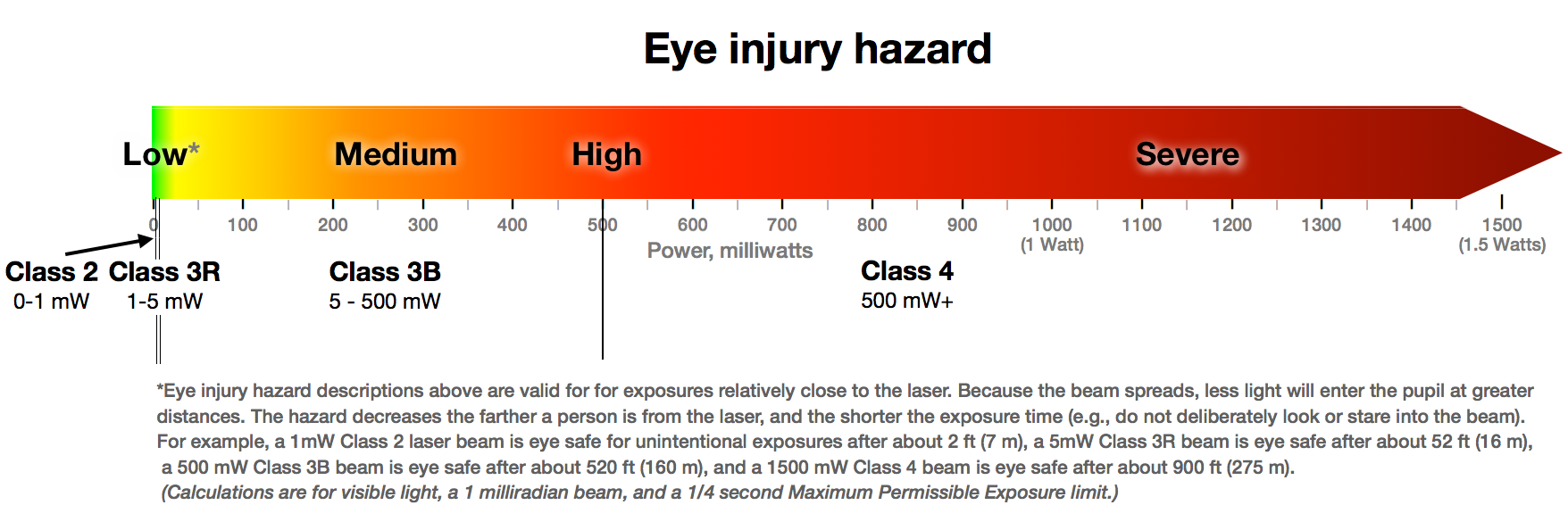

雷射模組安全概覽

IR 雷射模組、RGB 雷射模組與線型雷射模組安全等級

- Class 1 / 1M: 在所有正常操作條件下安全,適合感測器或掃描器應用。

- Class 2 / 2M: 可見光功率低於 1mW,短時間意外照射不會造成危險。

- Class 3R: 功率可達 5mW,避免直視光束,需謹慎操作。

- Class 3B / Class 4: 僅限工業用途,需配戴護目鏡並遵循嚴格操作規範。

IADIY 所有雷射模組均符合 IEC 60825-1 安全標準,並於適用地區完成 FDA 註冊,確保消費者與 OEM 專案使用的安全與合規性。

👉 想了解雷射模組安全標示與詳細規範嗎?

雷射模組採購指南:二極體、VCSEL、高功率

尋找適合的雷射模組 – RGB、IR、線型雷射與客製化解決方案

IADIY 提供完整系列的雷射模組,包括 RGB 雷射二極體、紅外線雷射模組、線型雷射模組,以及客製化雷射模組解決方案。本指南幫助您快速了解雷射模組結構、選擇合適型號,並探索客製化選項。

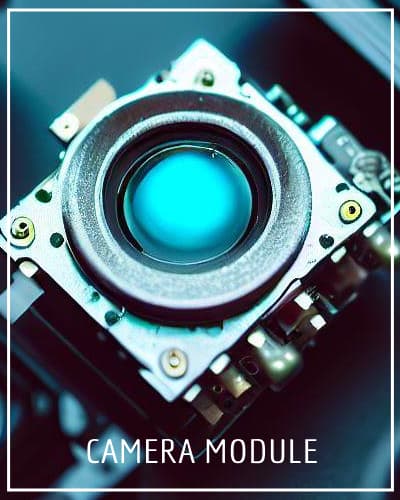

基本結構 - 典型二極體雷射模組包含:

- 雷射二極體:決定波長與功率(例如 405nm~1550nm)。

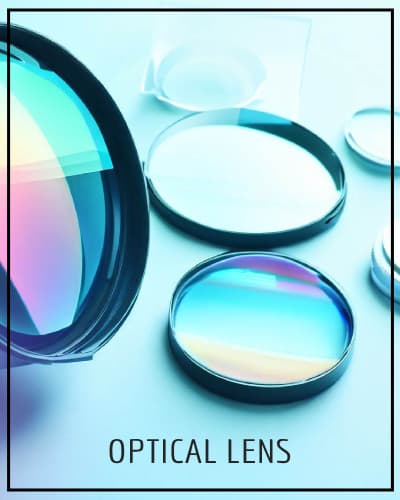

- 準直/光學透鏡:聚焦光束、生成雷射線或 DOE 光學圖案。

- 驅動電路:確保輸出穩定(支援 APC/ACC)。

- 機械外殼:決定散熱能力與光學對準精度。

雷射模組類型

- RGB 雷射模組:多波長輸出,用於照明、投影與對準系統。

- 紅外線(IR)雷射模組:780nm 到 1550nm 波長範圍,用於感測、測量或不可見光應用。

- 線型/十字線雷射模組:用於定位、機器視覺等,可選擇光束角度(例如 40°、60°、110°)。

- 客製化雷射模組:可依需求設計光學、調變、機械與散熱規格。

無論您需要精準點光、雷射線、十字線或複雜 DOE 圖案投影,我們可根據成本與效能協助優化雷射模組選型。

選擇雷射模組指南

- 應用場景:明確用途——視覺對準、照明、感測、標記。

- 波長:符合可見光或紅外線需求(例如 520nm 綠光,940nm 紅外線)。

- 功率:考慮眼睛安全與所需強度。

- 光束型態:點光、雷射線、十字線或圖案。

- 使用環境:外殼材質與散熱設計,適應不同應用條件。

找不到所需型號?聯絡我們 提供需求。我們支援小批量訂購、樣品測試及完整客製化開發。