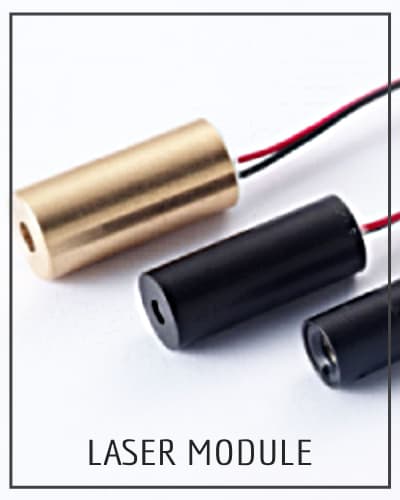

雷射模組工程

Laser Modules List: Diode Laser module, Infrared laser module, IR laser module, Laser line module, Laser line generator, Cross line laser module

Laser Modules Guideline introduces IADIY's laser module product line including RGB diode laser module, infrared laser module, line laser module, and customized diode laser module for convenient search and comparison by laser modules features list. You can open the laser modules guideline accordion to review the laser modules list and related laser diode module introduction and explanation.

More diode laser modules with different wavelengths and power options are available additionally to the standard laser diode module types. We also support the custom made laser modules as your requirements. Please send your requirements to us or leave the message in comment below. We'll reply to you soon!

Welcome to visit our laser modules online store: https://www.iadiy.com/laser-module

IADIY provides standard laser modules that are convenient for quick and easy orders of samples or small quantities on our Online-store.

We also provide and welcome orders of custom made laser modules with any specification requirement. If you can not find the laser module that fits your application, please email your inquiries to sales@iadiy.com and briefly describe your requirements or applications to us. We will reply to you in a very short time (usually within two working days).

Laser Module Introduction

There are 2 major kinds of laser modules on the market: laser diode modules and DPSS modules.

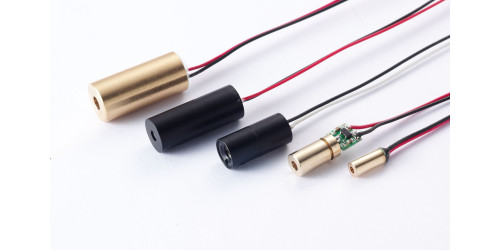

What we call what we call "Diode Laser Module” or "Laser Diode Module” is a device comprising a laser diode that can be connected to a power source directly.

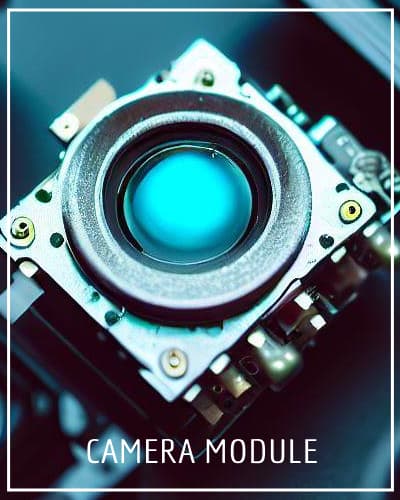

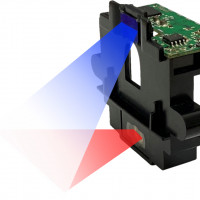

A "Laser Diode Module" usually comprises a laser diode, a driver circuit board, an optical lens (a laser collimator lens, a laser line generator or a laser pattern generating DOE (Diffractive Optical Element)) and mechanical parts. In high power laser modules, an additional TEC is also included for heat dissipation. The laser light emitting from the laser diode has a wide divergent span angle, therefore most applications require a laser collimator lens that will converge the laser light into a collimated laser beam. In the event of applications that would require a non collimated laser beam, IADIY also designs other complementary optical components to be assembled after the collimated laser beam, in order to achieve the desired pattern.

Another advantage of full laser diodes modules compared to single laser diodes is the presence of a specific driving circuit for the laser diode. Laser diodes are easily damaged components that need suitable working voltage and current supply in order to reach a stable output power, especially when considering the eye safety certifications.

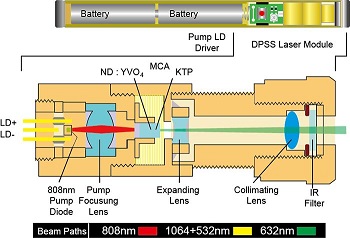

The other main kind of laser module uses DPSS (Diode-pumped solid state laser) technology. This DPSS laser modules are mostly applied in high power applications or designed for specific wavelengths.

Laser Diode Module Structure

- a laser diode

- an optical lens

- a laser driver circuit

- optical and mechanical properties

Common DPSS Laser Modules

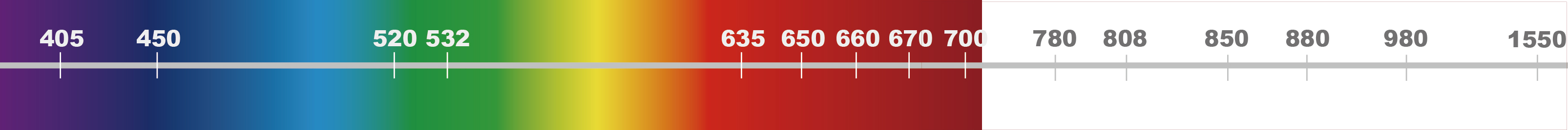

Electromagnetic radiations with wavelengths in the range of 400nm to 700nm are perceived by human eye as visible light. Lasers usually show a very narrow wavelength spectrum. A laser diode emits only at a determined wavelength emitted, depending on the semi-conductor material it is made out of. DPSS laser modules use crystals to modify a laser diode wavelength into a different wavelength.

Electromagnetic radiations with wavelengths in the range of 400nm to 700nm are perceived by human eye as visible light. Lasers usually show a very narrow wavelength spectrum. A laser diode emits only at a determined wavelength emitted, depending on the semi-conductor material it is made out of. DPSS laser modules use crystals to modify a laser diode wavelength into a different wavelength.

The most common solid state laser in use is the 532 nm DPSS green laser module. A 808 nm wavelength infrared laser diode injects light into a neodymium-doped crystal which then outputs a 1064 nm wavelength light, thanks to the properties of neodymium ions. This light frequency is then doubled by using a nonlinear optical process when going through a KTP crystal, thereby producing 532 nm light (When a frequency doubles, the corresponding wavelength is halved). Green DPSS lasers usually show ~20% efficiency (although some lasers can reach up to 35% efficiency). For example: a green DPSS laser module using a 2.5 W laser diode would output around 500 to 900mW of 532 nm light.

Blue DPSS Lasers use a similar process, except that the 808 nm light is converted by the neodymium crystal into 946 nm light (by selecting other properties of the neodymium), which is then frequency-doubled to 473 nm by another crystal (beta barium borate or lithium triborate crystal). These last materials show lower gains, hence DPSS blue lasers are only around 3-5% efficient, and the overall output power will be lower.

Yellow DPSS Lasers use an even more complicated process. An 808 nm diode generates 1,064 nm and 1,342 nm light, which are then combined together to become 593.5nm. The yellow DPSS lasers show even lower efficiency due to their complexity (around 1% efficiency), and are also more expensive. Another method to achieve yellow laser light is to combine 1,064 and 1,319 nm light, which are then summed to 589 nm. This process is more efficient: about 3%.

1. Laser diode:

-Main characteristics of laser diode: wavelength, output power, operating temperature

(Our laser diodes product list at https://www.iadiy.com/custom-laser-module, and other characteristics of laser diode like divergent angle, mode,and detsils please refer to the laser diode introduction. We can provide diode laser modules with wavelengths comprising 405nm, 450nm blue laser module, 520nm green laser module, 635nm, 650nm red laser module up to 1550nm infrared laser module and a laser module driving power can be equal or smaller than its laser diode operating power (as stated on the corresponding laser diode data-sheet).

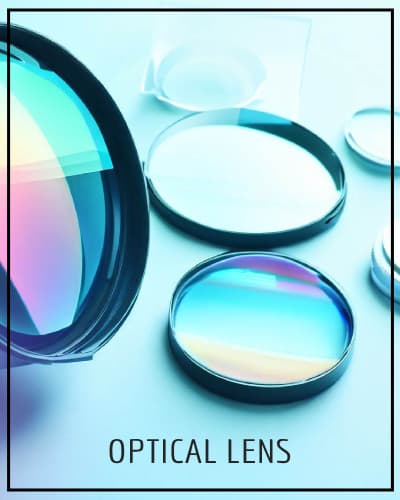

2. Optical Lens: Collimating Lens + Other Function Lens (Laser Line Generator, Laser Pattern Generator, or Special Feature Function Optical Components)

The following are the basic optical specifications that we need to agree upon before starting any laser module production.

- Main characteristics for the beam collimation: divergence angle, laser spot size.

- Choice of the laser pattern: laser dot, laser line, laser cross line, or any kind of laser pattern achieved through using DOE (Diffractive Optical Elements).

Laser Collimating Lens, Laser Collimator Lens for Laser Collimation Beam

Usually the emitting laser light from the laser diode is divergent, and most applications need the laser beam as a straight light beam. Then it needs the collimating lens to focus the divergent laser light to a very small divergent angle we called laser collimation. The laser beam divergent angle, beam spot size, even laser line width or DOE laser pattern sharpness depend on the laser collimation performance. The collimating lens is the key for the collimated beam requirements. The collimating lenses selection you can refer to the Optical Lenses Store.

Laser Line Module / Laser Line Generator / Cross Line Laser Module properties:

The laser line module projects a span angle laser line pattern. The length of laser line depends on the span angle and the distance, longer as farther distance and bigger span angle. The standard span angle of IADIY line laser modules have 40°, 60°, 90°, 110° can be chosen. The standard line laser module series we only accept the different span angle customized no other special modifications. As the real applications most customers have the requirements for the laser line width, laser line central accuracy, laser line straight accuracy and the laser line power uniformity. Higher accuracy would cause much time for the line laser module alignment. Especial the requirement of laser power uniformity would consider using the different level laser line generator lens. If you have these requirements please take the reference of our high end line laser modules product line. And send your application and detail requirements to us. We’ll try to optimize your requirements to modify the line laser module as the most cost efficiency for your application.

-Main characteristics of line laser module: line laser span angle or the length, and laser line width, laser line straight (bend) accuracy at working distance, laser line power uniformity range, boresight requirements: central, tilt, rotation requirements.

For the IR laser line module IADIY specially designed the laser line generator DOE for the infrared detection application like robot, gesture, and motion detection. It has the better power uniformity and high quality features for production. The IADIY economic scale of laser modules can provide you the best cost efficiency IR line laser module.

※ For line lasers, specifications such as laser line width, laser line span angle, laser line uniformity, cross line center, mechanical requirements or original marking can be additionally modified.Our standard laser line module diameter is defined at 9mm but all dimensions can be adjusted according to your needs.

Laser Pattern Generator (DOE Laser Patterns)

You can check some of our available specific DOE laser patterns at our dedicated page for DOE: sales@iadiy.com

※ Spot size: The laser spot size has a direct relationship to the distance of projection. If you can define the operating distance of your laser, the we will adjust the focus of the optical collimating lens to meet your application requirements. IADIY can calculate these parameters for you and let you know the possible outcome for your further evaluation.

※ IADIY has the optical design capacity to design and create new optical components such as Laser Collimating Lens, Diffractive Optical Elements, etc.. according to your requirements. If you had any questions, please don't hesitate to let us know.

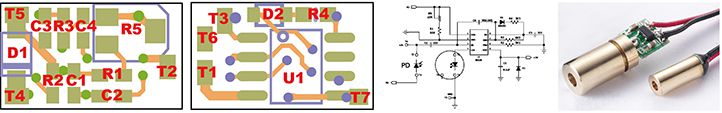

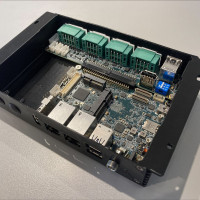

3. Laser Driver Circuit:

The driving circuit of the laser modules can be either APC (Auto Power Control) or ACC (Auto Current Control). An APC driver controlled laser module will automatically adjust the input current in order to output a constant value of optical power. An ACC driver controlled laser module will in another way have a constant value of input current, while the output power may be a percentage variable by temperature change.

Apart from CW mode (continuous wave mode), our laser modules can be designed to input a TTL modulation if needed. It can be fixed to run at a certain frequency (Hz) or a specific duty cycle, or can it be alternated via an external PWM input. Most applications major concern the laser power for eye safety or laser sensing. It needs to consider a stable output laser power or to adjust the power for the application requirement. Usually we'll suggest the APC driving circuit for this kind application. Or you may need to add an external photo diode monitoring the power for the control. Because the laser diode emitting efficiency would vary as the temperature, environment and life time. You need to monitor the real output power just can keep it stable as you need. The driving current only for the reference can not exactly equal to the laser output power.

-Main characteristics of laser driver circuit: operating voltage range, CW or Pulse modulation mode (TTL/PWM signal control: frequency range), driving current requirements, APC or ACC mode, laser module safety or circuit protection requirements.

Laser Output Power

A laser output power can be measured with a Power meter. Lasers can work in CW mode (continuous mode) or in a pulsed mode. Pulses power can be accounted on the basis of their average power or on the peak power of each pulse. Average lasers power ranges from <1mW for laser pointers and other consumer products to several kW for laser cutting applications or laser weapon systems, etc.

In laser applications the laser power control is an important feature, which is why the laser modules usually need specific driving circuits. Also, the laser diodes output power is sensitive to the environment temperature. We usually regulate the laser modules through an APC control method (Automatic Power Control) for <5mW applications and for eye safety certification. Such circuit requires one photodiode to measure the laser output power and feedback it to the driver and adjust the current so as to achieve a stable output power range. Applications with pulse modulation can also be controlled in a stable average output power thanks to the photodiode feedback.

Another laser driver type uses the ACC control method (Automatic Current Control) which is used in higher power laser modules (>10mW) for applications that can bear larger power variation, but that may not suitable for eye safety certification.

IADIY also supplies laser modules with variable output power, which can be achieved through digital modulation or analog modulation control. Custom made design can also be prepared according to your requirements, don't hesitate to contact us at: sales@iadiy.com

4. Optical and mechanical properties:

The laser module casings can be designed into many shapes and with different materials, their surfaces can be treated for different operating environments like anodization for electrical isolation etc. Some differences in a laser module casing design might help to reach different operating temperatures as the heat sink to offer the best protection for the inner components. And there are some optical features are deigned and aligned by the mechanic structure like focal distance, boresight (coaxial tolerance), laser line features will increase the mechanical dimension size and complexities.

-Main characteristics for mechanical requirements: dimension requirements, boresight or called coaxial angel accuracy of laser module.

Laser Safety

From the first lasers in 1964, it was clear that this light source had a power not only to do the required job, but that could also be very dangerous if operated improperly. Laser safety guidelines were written for consumers, and power levels are usually written for visible-light, continuous-wave lasers. Laser are now divided into Class 1, Class 1M, Class 2, Class 2M, Class 3R(3A), Class 3B, Class 4. For pulsed lasers and invisible wavelengths, other power limits may apply. In the USA it is considered that Class 1 to Class 3R(3A) lasers are safe for consumers, while the EU requires lasers to be Class 1, Class 2, Class 1M, Class 2M for consumers products. It is suggested to people working with class 3B and class 4 lasers to protect their eyes with safety goggles, which are designed to absorb light of a particular wavelength.

The main characteristics and requirements for the classification system as specified by the IEC 60825-1 standard are listed, along with typical required warning labels. Additionally, classes 2 and higher must have the triangular warning label shown here and other labels are required in specific cases indicating laser emission, laser apertures, skin hazards, and invisible wavelengths.

As the professional laser module manufacturer, IADIY standard laser modules all can fit the eye safety requirements and support the customer to apply the certification of your laser products.

Leave a Comment